On November 5, 2022, the final exam (dissertation defense) of the doctoral thesis of Rafal Popiel, M.Sc., entitled. “Quality control of threaded joint assembly processes in the automotive industry by empirical modelling methods“. The thesis was supervised by Prof. Grzegorz Dziatkiewicz, while the reviewers were Prof. Adam Hamrol, from the Poznań University of Technology and Prof. Wacław Gierulski, from the Świętokrzyska University of Technology.

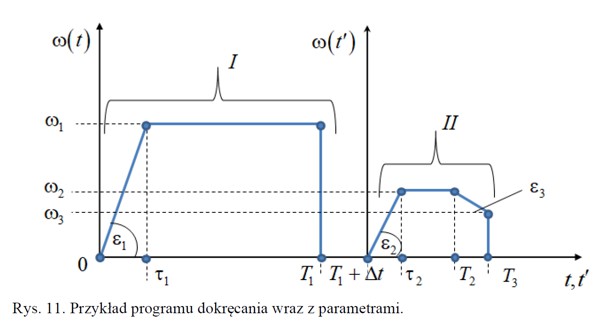

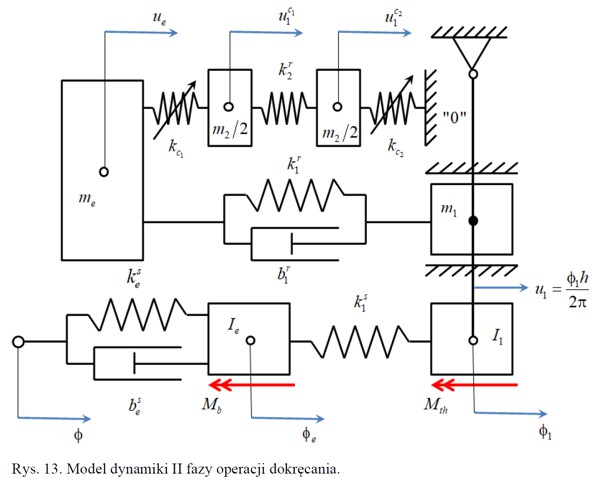

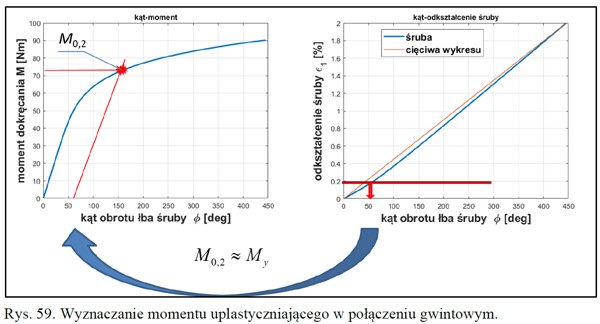

The dissertation considered the issues of quality control of threaded joint assembly processes in the automotive industry using empirical modelling methods. Mathematical models of phenomena occurring during the assembly process, which are essential from the quality point of view, are shown. In particular, the tightening operation, characterized by complex non-linear dynamics, and the quality control operation were considered. It has been shown that the introduced models are very complex, require the identification of many difficult-to-measure parameters, and practically cannot be used in the conditions prevailing on assembly lines in serial production. It has been hypothesized that empirical modelling methods can effectively and economically efficiently control the quality of the considered class of processes. Several measures for the quantitative assessment of the quality of the process were introduced, easily identifiable with the currently used tools used to automate assembly processes. These tools allow performing tightening operations with programmable mode and measuring of the so-called tightening characteristics in the form of the relationship: dynamic tightening torque – the angle of rotation of the screw head. Thanks to this, it is possible to determine quantitative measures of the process quality. The complexity of the process and its accompanying phenomena also require the analysis and control of measurement systems. It requires using unique statistical methods, particularly the nested analysis of variance, which is necessary due to the uniqueness of the measurements carried out during the tightening operation. The application of statistical process control methods in the field of joint quality control operations using static control torque measurements in the case of the grooving effect is also shown. A procedure for detecting a change in the quality of supplies was also developed, in terms of tribological properties of the system, using the linear regression method with a dummy variable for the connection operational stiffness model. Further, procedures for determining the so-called limit tightening torques, the exceeding of which causes plastic deformation in the joint. Problems of optimization of assembly processes were formulated using the Taguchi method and response surface. The developed formulations, methods and procedures may be applicable in industrial engineering; in particular, they may be helpful for engineers applying quality control methods in the automotive industry.