On 13 March 2024, at 11:00 a.m., the thesis defence of Tomasz Zadorożny, M.Sc., entitled: “Minimization of thermal distortion by intelligent optimization of the arrangement of fixing points in the area of the welded component” took place.

The dissertation was supervised by prof Mirosław Szczepanik, PhD , while the reviewers were prof Leszek Łatka, from Wrocław University of Technology, prof Dariusz Fydrych from Gdańsk University of Technology and prof Andrzej Kubit, from Rzeszów University of Technology. The Doctoral Committee has passed motions to the Council of the Discipline of Mechanical Engineering to grant the degree of Doctor of Technical Sciences in the discipline of Mechanical Engineering for Tomasz Zadorożny, M.Sc., the degree of Doctor of Technical Sciences in the discipline of Mechanical Engineering.

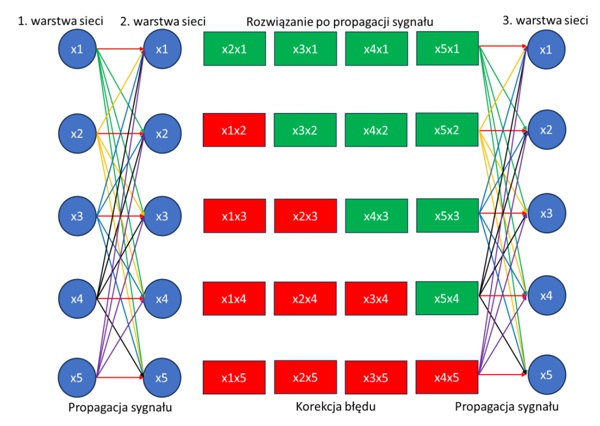

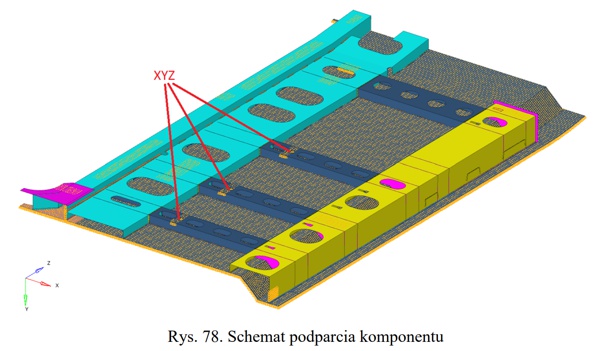

Optimization of technological processes is extremely difficult and time-consuming due to many factors affecting their course. A properly conducted simulation of the process along with its optimization allows you to improve the production stage, contributing to a significant reduction of costs related to technological time and potential repairs. This paper presents a description of the problem of permanent thermal deformation after the welding process. Various types of defects and methods of their repair are discussed, pointing to the clear need to reduce them, which translates into stabilization of the production process and improvement of product quality. In the following part, a description of the developed system for simulating the welding process and optimizing the arrangement of fixing points in the area of the welded component in order to minimize permanent deformations was made. To implement the task, the commercial HyperWorks software was used, which was combined with proprietary algorithms supporting the process of creating a numerical model and optimization. The paper also presents a theoretical example for a relatively simple construction for which the procedure and actions during the process simulation and optimization are described in detail. Additionally, to validate the developed system, a complex numerical simulation of the railway vehicle body shell welding process was conducted, along with optimizing the selection of fixing points. The analysis precisely replicated real conditions and parameters used during the manufacturing process. The analysis accurately reproduced the actual support conditions and parameters that are used during the production process. The individual stages of production and the welding sequences of individual components are also taken into account. The obtained results were compared with the actual measurements of the structure after the completion of the process, which allowed to confirm the validity of the assumptions made during the creation of the discussed system. The presented optimization system and the approach to the problem indicate that at the initial stage of designing the structure and planning the production process, it is possible to properly select the arrangement of fixing points to limit thermal deformations. The discussed solution has been successfully implemented in the company.