ABOUT US

Our research team deals with applied research on the processing and treatment of secondary raw materials in order to separate and recover individual substances and return them for reuse.

The research and design work is carried out based on a business model focused on extending the product life through reuse, repair, recycling and recovery, as well as the use of secondary raw materials in the production process. In principle, they are to be consistent with the principle of sustainable production, which is understood as optimal production in terms of efficiency, impact on the environment and employees, as well as investment and process costs. The basic tools for production optimization are life cycle analysis (LCA) and life cycle cost analysis (LCC). The Laboratory’s activities include research into physical and physicochemical recycling using mineral engineering processes (magnetic, electrostatic, gravity separation and flotation, flocculation, coagulation).

OPERATION PROFILE

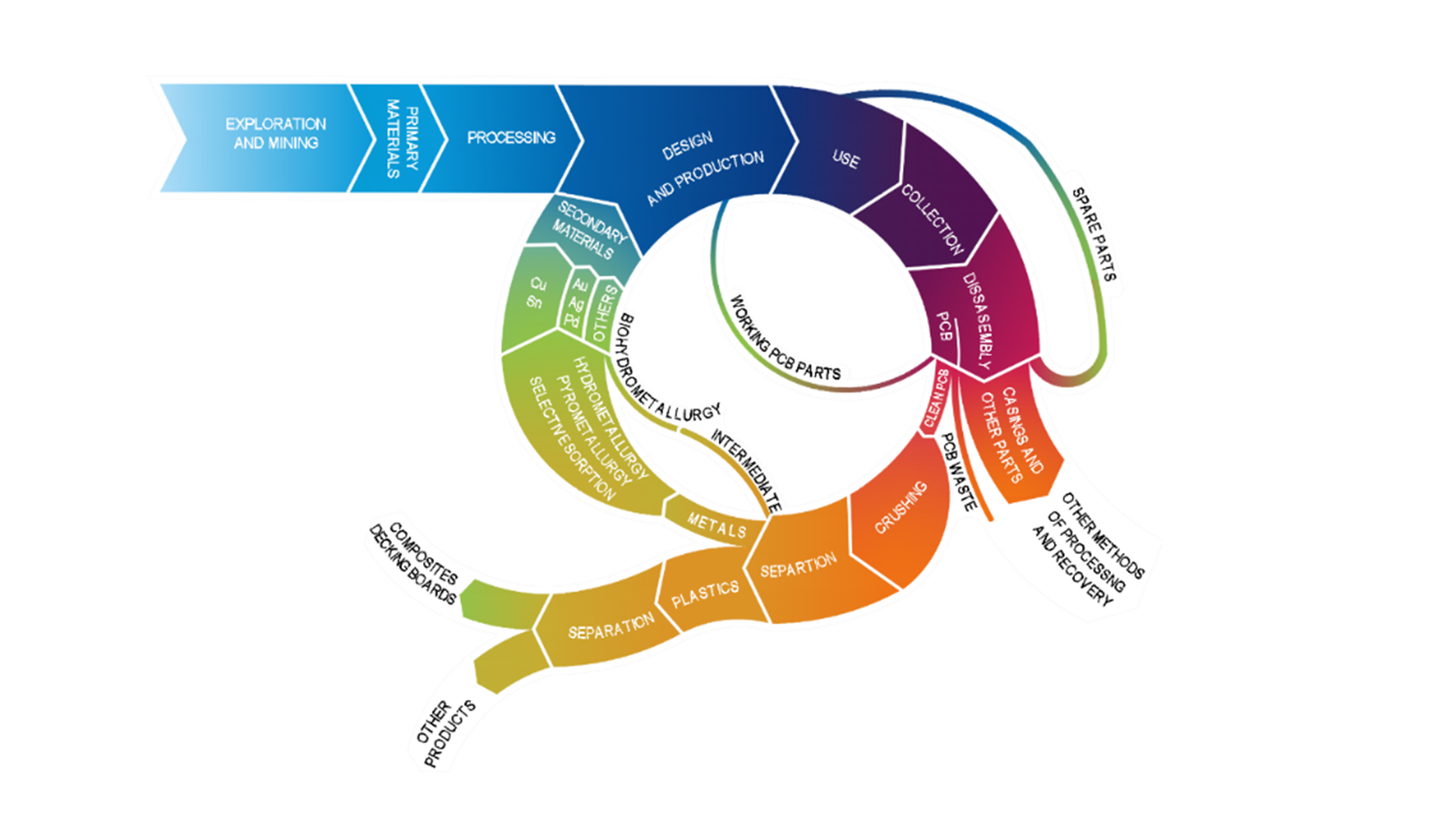

Due to the increasing amount of waste and the possible shortage of various raw materials, sometimes referred to as critical, the assumptions of the circular economy were introduced, which is based on a business model aimed at extending the life of the product by reusing, repairing, recovering and using secondary raw materials in the production process. Therefore, it was decided to loop the economy to change the product life cycle. According to the new approach, the produced good after application is to be used in the next production cycle, which consequently reduces the amount of waste generated. An example of the application of this concept for printed circuit boards designed and implemented in our laboratory is presented below.

Recycling of printed circuit boards (PCBs), an example of using mineral engineering in urban mining

The Laboratory of Recycling and Circulation Economy is equipped with a conventional, but also with innovative research infrastructure, which allows for solving difficult problems and technological challenges and the implementation of the presented tasks on a laboratory and quarter-technical scale. In cooperation with other research units and institutions with which cooperation agreements have been signed, we can implement the results of research conducted in the field of broadly understood mineral engineering and recycling, and achieve technological readiness at the deployment level.

Our laboratory base and research team enable the implementation of innovative research works in the field of obtaining raw materials from secondary and primary sources as well as their processing and modification in order to produce new goods. The development of new methods and technologies for the processing of waste electrical and electronic equipment, application and processing of by-products of the production of various goods, recycling of batteries, neodymium magnets, plastics and others requires research at all levels of technological readiness in the search and verification of new solutions, their implementation and determination of critical process functions, control and automation of machines and devices as well as limiting and controlling the impact on the natural environment.

RESEARCH AND DESIGN WORKS

The results of the research and design work are consistent with the objective of promoting sustainable development, specified in Article 11 of the Treaty on the Functioning of the European Union (TFEU), and with the “do no significant harm” principle written in the EU Regulation1. The designed recycling installations contribute to two out of the six environmental objectives of Regulation (EU) 2020/8522 of the European Parliament and of the Council (Article 9), and thus make a significant contribution to reducing the impact of designed processes and products on the environment, without causing significant harm to any of the environmental objectives. Therefore, the designed recycling installations can be considered as supporting sustainable development (Article 3 of the Regulation).

Objective 1: Climate change mitigation:

In the planned R&D works, we make sure that the designed and implemented technological processes operate with much higher energy efficiency, thus reducing greenhouse gas emissions.

Ojective 2: Circular economy, including waste prevention and recycling:

In our R&D activities, we focus on designing and implementing technological processes to be resource-efficient and to have the least possible impact on the environment.