Start - Aktualności - Project as part of the Weave-UNISONO competition at the Silesian University of Technology

Project as part of the Weave-UNISONO competition at the Silesian University of Technology

Will modern MAX coatings be used for elements of aircraft engine turbines? An international team of scientists will answer this question. The project is carried out with the participation of researchers from the Silesian University of Technology.

MAX type materials are a new group of materials that fill the gap between ceramic materials and metals. They are resistant to thermal shocks, oxidation and corrosion, and are characterized by high resistance to fatigue and creep. For this reason, they can be used in high-temperature environments, e.g., as protective coatings for stationary and aircraft turbine components.

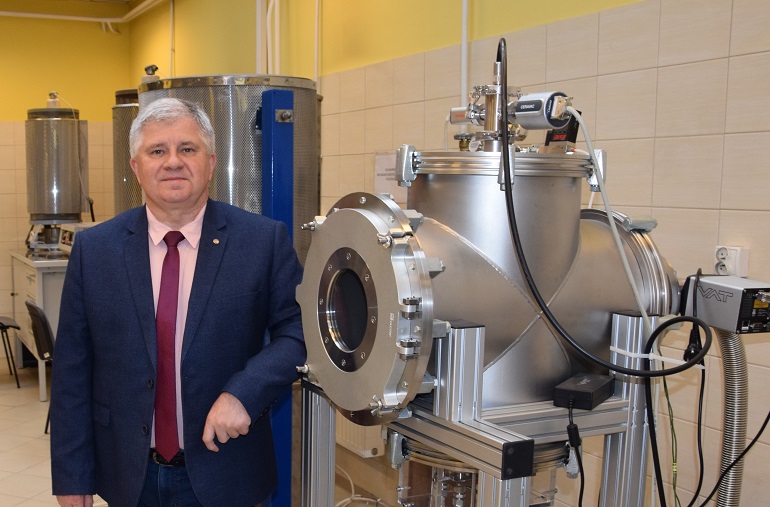

The project entitled " The use of nanolaminate coatings for high-temperature applications" is carried out as part of the competition of the National Science Centre entitled Weave-UNISONO, 2022 edition. The project involves partners from the Łukasiewicz Research Network, the Upper Silesian Institute of Technology - the leader of the consortium and the Silesian University of Technology, as well as from RWTH Aachen University and the German Aerospace Centre (DLR) from Germany. The project manager at Łukasiewicz - GIT is dr Eng. Radosław Swadźba, while at the Silesian University of Technology the project is headed by dr hab. Eng. Bogusław Mendala, prof. of the Faculty of Materials Engineering, Department of Materials Technologies.

Scientists will conduct research on the production and degradation of MAX coatings at high temperature. - For the first time, three different PVD technologies available in partner institutions in Poland and Germany will be compared, as part of the project, scientists will use modern research methods available in the country and abroad - said dr hab. Eng. Bogusław Mendala, prof. SUT.