Start - Aktualności - Bone-forming and bioresorbable implants revolutionizing medicine

Bone-forming and bioresorbable implants revolutionizing medicine

A surgical implant that grows over the patient’s bone and disappears from the body after a dozen or so months – this is not science fiction, but the result of the work of a group of scientists, among others from the Silesian University of Technology. Dr Eng. Małgorzata Muzalewska and dr hab. Eng Marek Wyleżoł, prof. SUT from the Department of Fundamentals of Machinery Design at the Faculty of Mechanical Engineering are part of the team that developed personalized 3D printed implants – bioresorbable and bone-forming. This innovative solution has already helped several patients in Poland and Ukraine.

A four-year-old girl from Mikołajów in Ukraine suffers from a terrible accident. Doctors save her life, but they can’t help a huge bone loss – as a result of the accident, the girl has a hole in her head, which makes up almost a third of the surface of her skull. The child is alive, but even a minor injury can be a deadly threat to her. Ukrainian neurosurgeons are looking for help abroad – in a war-torn country, such complicated cranioplastic surgeries are practically impossible to carry out. Bone defects are usually supplemented with native bone, taken from other parts of the bone system of the operated patient. Such procedures are time-consuming and due to the destabilization of the health care system in Ukraine, they are practically not carried out at present. In addition, the bone loss is huge, and the child is growing, so the procedures would have to be carried out repeatedly. There are no implants that would not deform the baby’s head during its growth, and multiple operations are physically exhausting for a small patient. Pavlo Plavskiy, head of the neurosurgery department of the National Specialist Children’s Hospital “Ohmatdyt” in Kiev, the largest such facility in Ukraine, contacts the Polish company Syntplant, which, among others, with scientists from the Silesian and Poznan University of Technology, develops bioresorbable biodegradable implants for bone reconstruction procedures as part of a scientific project. The company has the appropriate material in the form of filament for 3D printers and the technology of manufacturing implants. There is no construction of the implant, which after implantation will "grow" with the child. The research team includes dr Eng. Małgorzata Muzalewska and prof. Marek Wyleżoł from the Silesian University of Technology and they are the ones who take up the challenge of developing an implant for a girl from Mikołajów. She is a biomedical engineer, he is a mechanical engineer. Using the latest virtual modelling technologies, they successfully develop models of bioresorbable bone implants. Their excellent cooperation will once again result in an innovative solution.

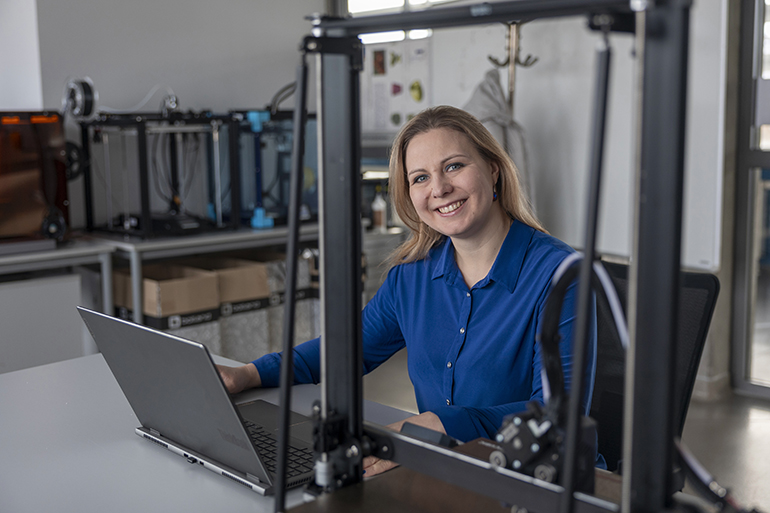

– My role is to model the patient’s anatomical structures – explains dr Eng. Małgorzata Muzalewska. – Because our implants are personalized, my work always starts with the results of CT scans. On their basis, with the help of specialized software, I develop a virtual anatomical model, then prof Wyleżoł, using haptic technology, creates an implant complementing the cavity, adjusted to the curves of a given bone.

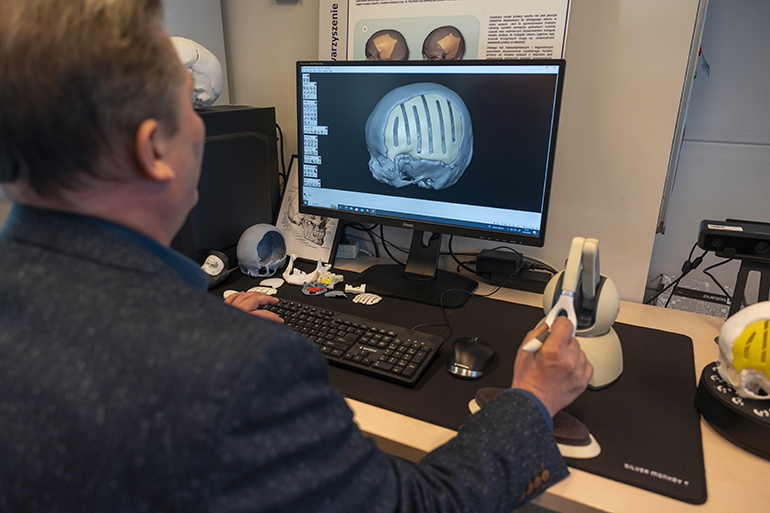

– Our ambition is to make virtual models, as well as implants implanted in patients, looking as anatomical and least technical as possible,” adds the professor, stressing that so far, he has been dealing with virtual modelling rather as a hobby for over 24 years. – We have at the University equipment for modelling implemented haptically. It is a very complicated and rarely used in Poland virtual modelling technique, perfectly suitable for creating models of skeletal system elements, i.e. those that do not have typical geometric features, characteristic for technique or mechanics.

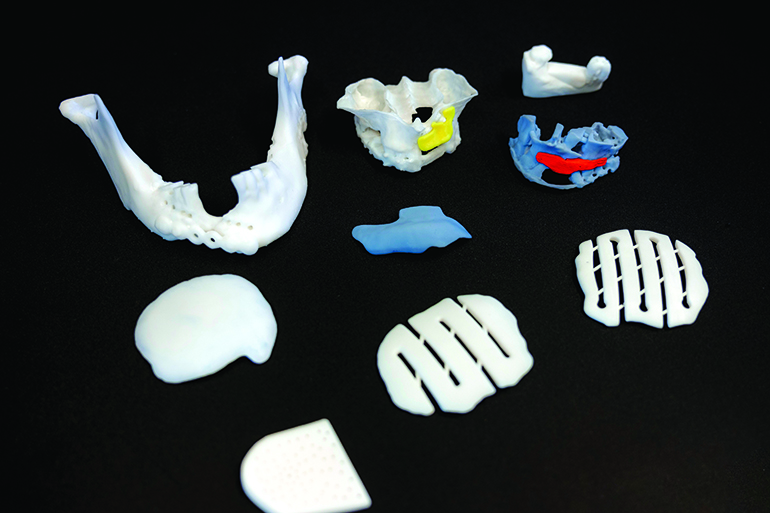

The result of the painstaking work of the scientists was to create for a small patient a model of the implant, whose construction was based on a system of connected flat ribs, arranged in the form of cranial curves. The researchers called the implant adaptive because it “grows” with the child. It is characterized by susceptibility to stresses occurring between the implant and the edge of the skull, expanding during growth. Thanks to the special grooves between the ribs, the implant can deliberately deform, which gives the body space for bone growth. The implant was successfully implanted in a 4-year-old girl at the end of 2022. In the following months, scientists from the Silesian University of Technology developed implants for two children, aged 6 and 8, which were also successfully implanted. The operations were carried out as part of social assistance, free of charge for patients, thanks to the funds from the grant. At the request of the doctors, for the sake of the patients’ welfare, information on innovative treatments was brought to light with a considerable delay. All three children are doing well, which means that the work of scientists has opened up new possibilities in the field of paediatric implantology.

“Our little patients are under constant care of doctors, they have regular tests carried out using computed tomography, which shows that our implants work, that is, they begin to grow over the native bone of children – does not hide the joy prof Wyleżoł. “All children feel good, we have direct contact with their doctors, and we are very happy that we have been able to help them.

Photo taken during implant surgery at the National Specialised Children's Hospital "Ohmatdyt" in Kiev. Material provided by Syntplant sp. z o.o.

The novelty of the implants developed by the team of scientists is that they are created from bioresorbable and bone-forming materials, i.e. they grow over bone tissue. The development and production of the material is carried out by a team of scientists from the Poznań University of Technology. The implants are made of modified polylactide (with multiple admixtures). Its main advantage is that it resorbs, that is, it safely disappears from the human body after about 18 months. The “scaffolding” of an implant made of hydroxyapatite, which is a substance contained in bones – their natural building block - remains in place. Hydroxyapatite from implants stimulates the one from the patient's body, which causes bone tissue to grow into properly designed spaces.

– What is also innovative is that from modified polylactide it is processed into filament, which we can use in 3D printers, thanks to which we are able to produce implants very quickly. Of course, this process takes place in sterile conditions, in a special chamber. After printing, the implant is still subject to radiation sterilization (it is possible to carry out only in Warsaw). After this process, it can be implanted into the patient’s body – explains dr Eng. Muzalewska.

Bioresorbable implants have already helped several patients and are successfully used in such fields of medicine as facial and maxillary surgery, neurology, or orthopaedics. They are ideal in cases where the current possibilities of medicine are exhausted. They are a rescue for patients after oncological treatment, genetic defects or after accidents. They can save lives, but also significantly improve their quality. As in the case of a young woman, who after a complicated mandible fracture in a traffic accident was sentenced to a deformed face. Doctors saved her life, but without a personalized implant, her jaw and teeth could not be restored. The researchers also modelled a fragment of the jaw of a patient with a lowered sinus, or a teenager with a cleft palate that has already undergone several unsuccessful treatments.

– We are in contact with doctors from the moment of creating models and construction of implants, to the operations on which we are present. It is a very interesting experience, bringing a lot and improving the process of modelling subsequent implants – explains dr Eng. Muzalewska. – Engineers in the operating room or in the dental surgery are there to possibly advise on the method of fixation of the implant, i.e. the method of attachment. Of course, we always plan it in advance, but during the procedure unexpected circumstances may occur, it is always a valuable lesson for us for the future.

Bioresorbable, bone-forming implants can be used throughout the bone system. Scientists are developing personalized implant models, and further operations are already planned.

– As a mechanical engineer, I am particularly pleased that my former hobby, consisting in virtual modelling, has found application in the field of medicine. This is not an ordinary situation and that is why I feel a little unusual, but I am very glad that my knowledge of virtual modelling has found application to the treatment of people – prof Wyleżoł does not hide the pride. – I have always said that science should serve man,– he adds.

– The satisfaction with this project is huge, because we see that what we do works and helps people, – adds dr Eng. Muzalewska. – Of course, health is our priority, but also those cases in which we can improve the appearance, improve the aesthetics, make us extremely happy. For a young woman, the opportunity to supplement a serious tooth loss is very important, it is a great satisfaction to see such a success.

The achievements of our scientists have already been widely echoed in the media, thanks to which more and more people, as well as medical institutions, are asking about the possibility of cooperation. Congratulations on your success!

You are also invited to listen to the Silesian University of Technology podcast with scientists.