Heat Treatment and Metallography Students Laboratory

- Name of laboratory: Heat Treatment and Metallography Students Laboratory

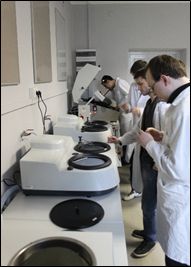

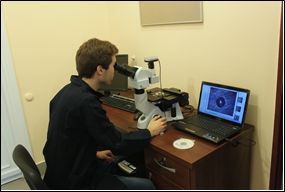

This is a didactic Laboratory created for the technological module Production Processes and Techniques. In the laboratory students carry out heat treatment processes such as annealing, quenching, tempering, supersaturation and/or ageing. The task of the students is to prepare materials for the next stages of the technological process and, thanks to a set of preparation devices, also for testing the microstructure and properties. The Laboratory is also equipped with a laboratory wire patenting line. The purchased software allows for simulate the heat treatment process and then the students independently, but under the supervision of the tutor, experimentally verify the simulation results. The aim of the classes conducted in the Laboratory is to evaluate the microstructure and selected properties of metal alloys at various stages of production and processing of details and semi-finished products produced during the course. Students evaluate, among others the influence of melting and casting parameters on the primary structure of castings, as well as the influence of selected stages of sheet and wire production as well as final heat treatment on the microstructure and hardness of manufactured semi-finished products. Independent realization of laboratory exercises also allows to master the principles of sampling for testing, methods of sample preparation in accordance with the requirements and methods of planning an experiment, and above all to improve the ability to select process parameters, inferring on the basis of the obtained test results and a critical assessment of the activities carried out. When evaluating the microstructure, students use the available computer image analysis software.

- Laboratory equipment (list)

- Water cooling metal cutting machine Remet TR60 INOX,

- Two station grinding and polishing machine Metalogis Forcipol 2 -2 pieces,

- Polishing machine Remet LS2,

- Metallographic microscopes equipped with a camera for recording microstructure images-3 pieces,

- Universal hardness testes ERNST NR3,

- Laboratory chamber furnace Carbolite ELF 11/14B/300, work temp. to 1100°C - 3 pieces,

- Laboratory wire patenting line. - Person responsible for Laboratory (contact details)

Associate Professor Agnieszka Szkliniarz PhD, DSc

e-mail: Agnieszka.Szkliniarz@polsl.pl

tel.: +48 32 603 44 06