Start - Start - Laboratories - Lab CK-14

Laboratory of the comminution processes control

Administrator's Name:

dr inż. Szymon Ogonowski

Laboratory description:

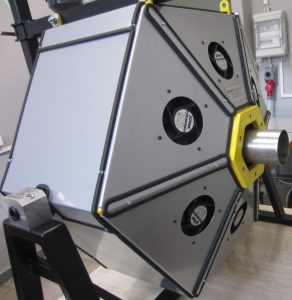

- Electromagnetic mill with a working chamber diameter of 100 mm (ELTRAF production, 2012).

- Installation of pneumatic transport of with milled material classification and recycling system (ControlWag, 2016).

- Measurement system and SCADA system with iFIX and Historian software (AMEplus, 2016).

- Accessories (ELTRAF, AMEplus, 2016):

- dedicated power supply cabinet and control cabinet with PLCs (on loan),

- prototype humidification system for milling material,

- prototype application system of grinding media,

- prototype heat recovery system and precision weighing

- sieving equipment.

Fields of expertise:

Dry grinding of bulk materials with low granulation

Conducted research and its potential application/use:

- Optimization of grinding quality (product graining) by selection of mill parameters, pneumatic conveying system and classification and recycling system.

- Transport control with indirect flow measurement.

- Energetic optimization and performance optimization.

- Quality control of milling by parameterizing the humidity and temperature of the milled material and application of grinding media.

- Support for quality control systems by heat recovery.

List of scientific and research equipment/apparatus:

- Electromagnetic mill D100 Eltraf

- Industrial VAcuum Cleaner ST-3

- Inertial separator Pro-mill

- Cyclone Pro-mill

- Transport system: screw feeder, rotary feeder

- Grinders dosage system with belt conveyour,

- Sampling system

- Power cabinet with inverter FR700

- Control cabinet with S7-300 and S7-1200 PLCs, HMI panel and other appliances

- Sensors: air humidity, velocity and pressure, temperature, level of bulk materials

- Industrial scale