POB5.T4 Simulation and modeling of processes,

including industrial processes

POB5.T4 Simulation and modeling of processes,

including industrial processes

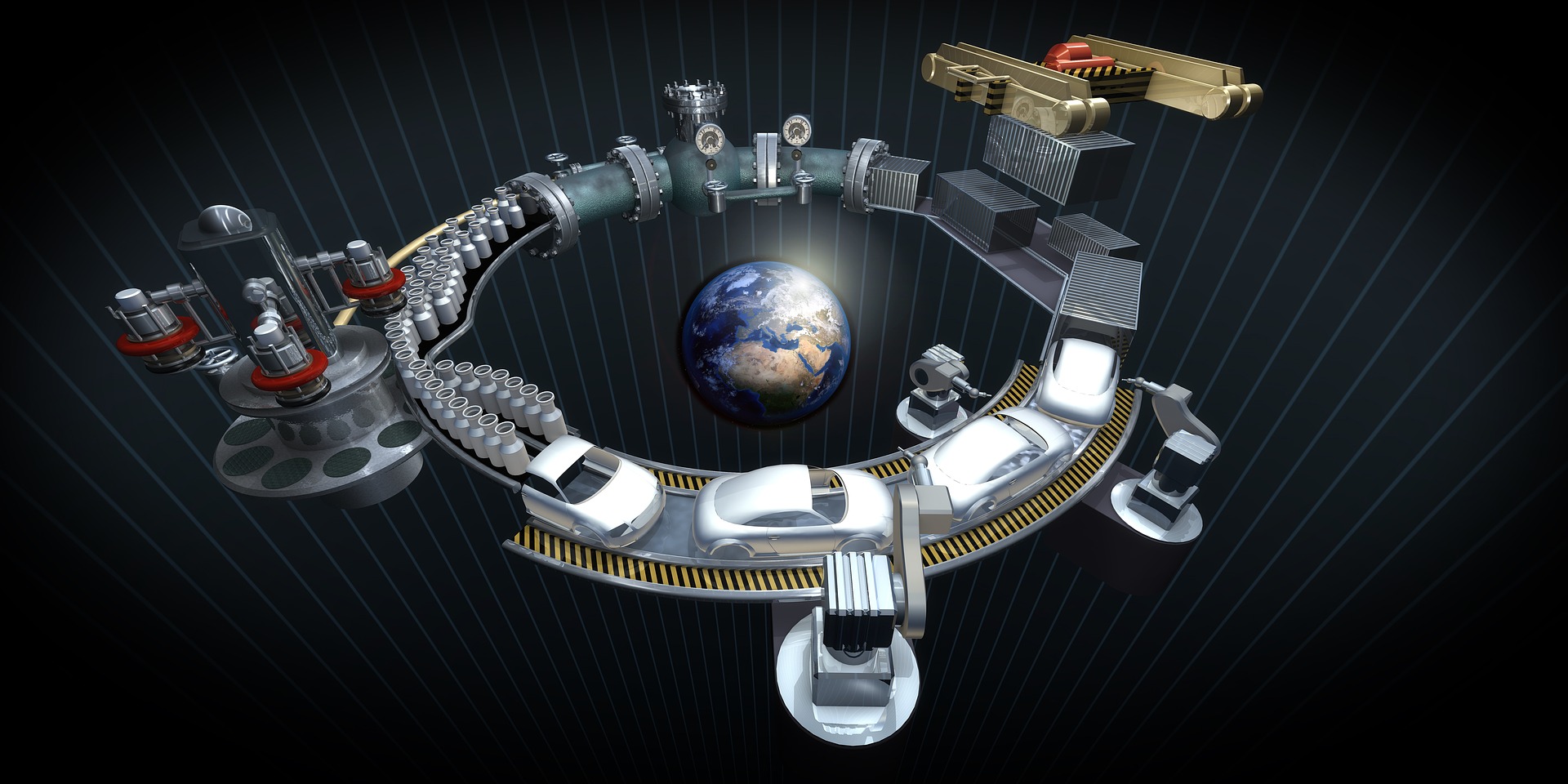

Effective implementation of automation and the Industry 4.0 concept is related to decision-making and implementation of new manufacturing technologies and new concepts of company organization. These activities are to lead to the transformation of the implementation of manufacturing processes towards solutions based on cyber-physical systems, integrating into the complete value chain, including manufacturing, logistics, warehousing, and distribution. As a result, it will allow to achieve a high level of flexibility and reconfigurability of systems. In this context, process modelling and simulation is becoming both a powerful verification tool to help implement changes and a way to implement the digital twin concept.

Research activity conducted in Simulation and modeling of processes sub-area within Priority Research Area POB5 focuses on several key issues:

- Development of automatic generation methods of production system simulation models and the use of computer simulation systems in the implementation of a digital twin as one of the main elements of an intelligent factory based on cyber-physical systems.

- Integration of data from multiple sources to automate the creation and dynamic update of simulation models; data are obtained from IT systems supporting management at various levels and in various areas, as well as directly from the operational level; data mapping and transformation methods in conjunction with the concept of a neutral data model are used in this area.

- Increasing the level of data integration between the digital and physical layer, from the Digital Model level, through Digital Shadow, up to the Digital Twin, where it is possible to directly and dynamically data flow in both directions, between a physical and digital object.

- Modelling and simulation of industrial control processes that allows for development of control algorithms, starting with classical, PID-based algorithms, through model predictive control, ending with modern algorithms using artificial intelligence, e.g., fuzzy logic or neural networks.

- Implementation of control algorithms in different programming languages and environments, from low-level languages used in embedded hardware, to modern graphical programming languages, popular in IoT environments, e.g. NodeRED.

- Physical modeling and numerical simulation of hydrodynamic phenomena occurring during industrial processes, in particular during smelting, secondary metallurgy and casting of liquid steel. Numerical simulations are carried out using the specialized ANSYS Fluent software.

- Modeling of forecasting the cutting jet deflection angle. The method consists in measuring the interaction of forces in real-time and using a mathematical model that analyzes selected components of cutting forces to determine the angle of deviation of the abrasive waterjet when cutting through the workpiece material. The cutting angle of the water jet directly relates to the deviation of the traces after the cutting process on the treated surface, i.e. the inclination angle of the striation visible on the treated surface after cutting.

- Controlling the process of rectification of buildings tilted from the vertical. The aim of the process is to bring the building object to the required position while minimizing deformation of the rectified structure.

Coordinator:

dr hab. inż. Damian Krenczyk, prof. PŚ

damian.krenczyk@polsl.pl